10

Years

R&D

150+

Mesh

High Precision Filtering

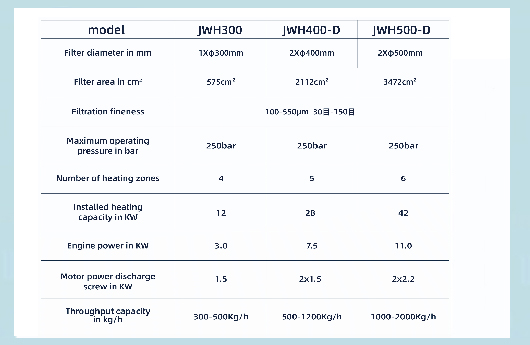

3400

cm2

Filtering Area Per Unit

2000

kg/hr

Maximum Unit Capacity

10+

Patents

Recycled Plastic Filtration Solutions

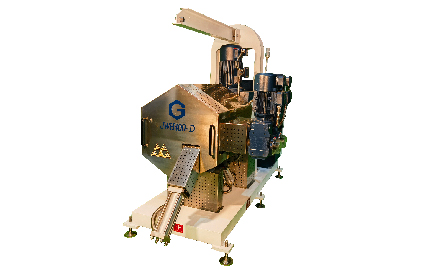

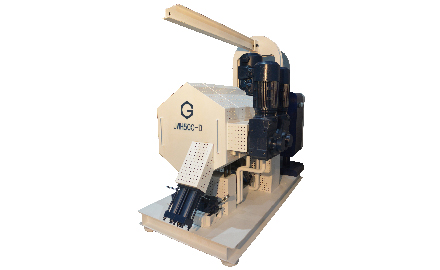

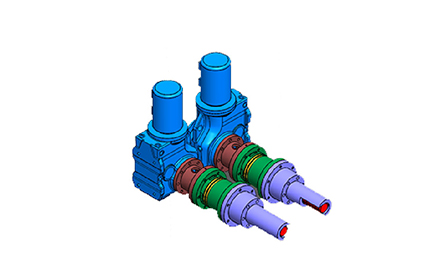

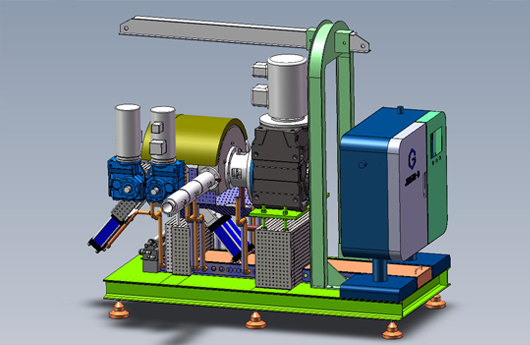

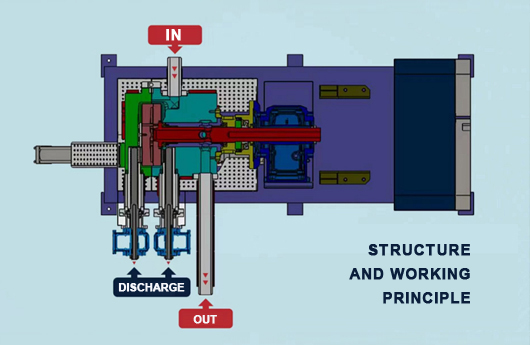

Patented Fully Automatic Melt Filter JWH Series

LESS INVESTMENT, LOWER OPERATION/MAINTENANCE COST, FAST DELIVERY TIME

Products Center

High performance | High precison | Quality assured

Solutions For Plastic Filtration

Ensure solving customer's problmes with rapid reaction service

Performance Of Dalian Jinguo

Our team is always avalaible to support you with our excellent service

Copyright © 2022-2025 大连梅曼科技有限公司 All Rights Reserved 辽ICP备2022006803号-1