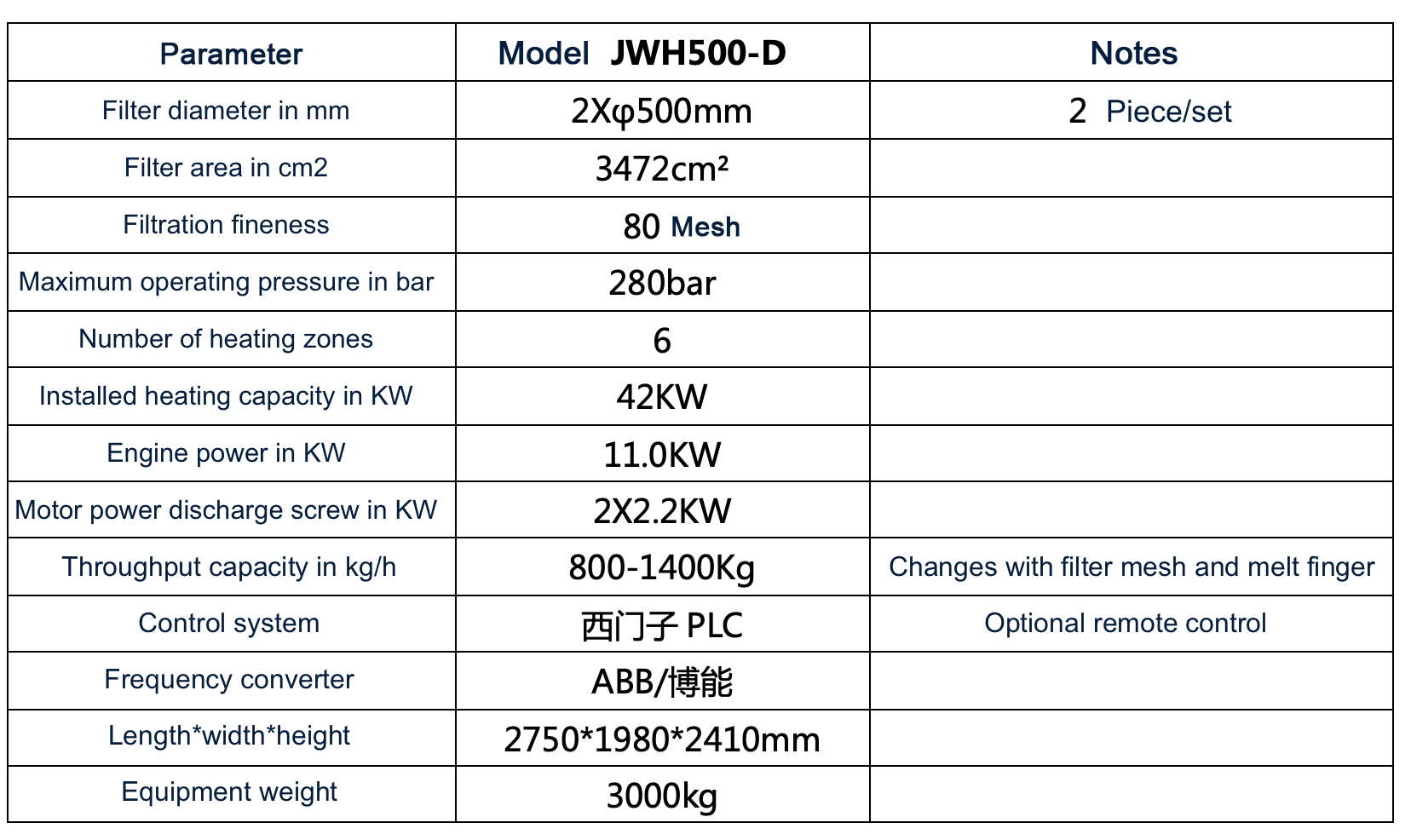

Product Model: :JWH500-D

Product Overview:Two-stage filter configuration. The first stage: traditional plate screen changer, the filtering precision is 5-6 mesh The second stage: JWH500-D automatic laser filter, the filtering precision is 80 mesh

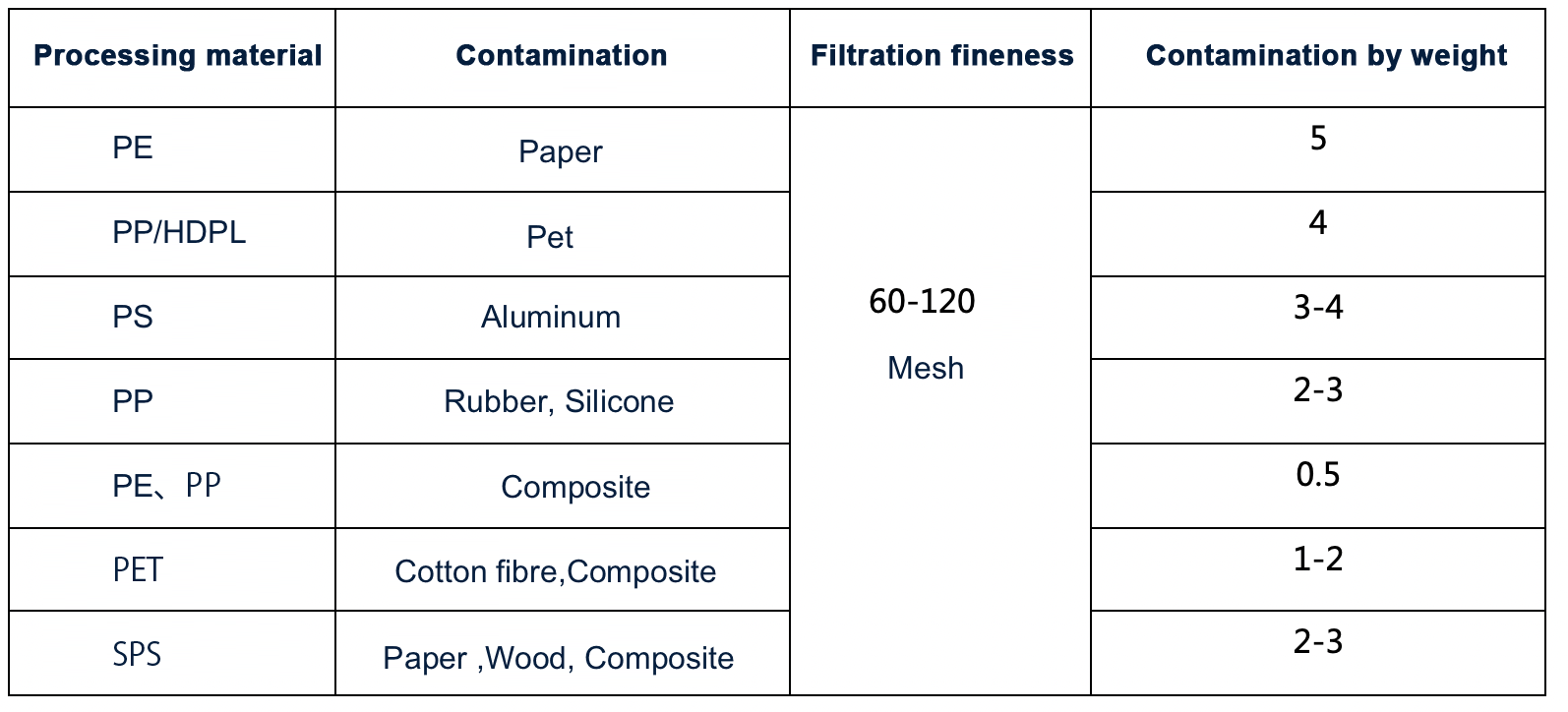

(1) JWH recycled plastic filter can handle various recycled plastics with pollutants up to 5%, including PE, PP, PS, ABS, HDPE, EPS, etc.

(2) The filter plate adopts ultra-high hardness composite material and laser technology, which can deal with various impurities, such as paper, wood chips, aluminum foil, tin foil, copper, rubber, silica gel, straw, cotton, etc.

(3) JWH's filtration, scraping, slag discharge and other processes are precisely controlled by fully automatic PLC, which improves the cleanliness of recycled plastics, greatly saves labor and energy consumption, and reduces the cost of consumables.

(4) JWH filter can be easily combined into the existing extrusion production line, regardless of single-screw, twin-screw, and various types of pelletizing systems or downstream devices

(1) Polypropylene and polystyrene plastics, no PVC, PVDC, EVA, and other materials, and plastic filters without grinding and corrosion pollution;

(2) Removable: paper, sawdust, aluminum foil, tin foil, copper, rubber, cotton wool, etc.;

(3) The size of material impurities should not be greater than 3mm;

(4) It is required that the pressure of the extruder can reach more than 15MPa;

(5) The machine only needs to be connected to the corresponding power supply. One-stop integrated mode;

Copyright © 2022-2025 大连梅曼科技有限公司 All Rights Reserved 辽ICP备2022006803号-1